As How to Gather Essential Supplies for Mushroom Cultivation takes center stage, this opening passage beckons readers into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

Embarking on the journey of mushroom cultivation requires careful preparation and the right tools. This guide is designed to illuminate the essential supplies needed at every stage, from understanding the fundamental requirements of growing mushrooms to setting up a thriving fruiting environment and managing post-harvest processes. We will delve into the core needs, substrate preparation, sterilization techniques, inoculation methods, and specialized equipment that will empower both novice and experienced cultivators.

Understanding the Core Needs of Mushroom Cultivation

Embarking on the journey of mushroom cultivation requires a foundational understanding of the essential elements that contribute to a successful harvest. Mushrooms, unlike plants, are fungi and have distinct requirements for growth. This section will delineate these core needs, outlining the fundamental principles and the primary categories of supplies that form the bedrock of any mushroom cultivation setup.Successfully growing mushrooms hinges on replicating their natural environment to a controlled degree.

This involves providing the right nutritional medium, maintaining optimal temperature and humidity, ensuring adequate fresh air exchange, and, critically, preventing contamination from competing microorganisms. These factors collectively create an environment where mushroom mycelium can thrive and fruit.

Fundamental Requirements for Successful Mushroom Growth

Mushrooms require specific conditions to germinate, colonize, and produce fruiting bodies. These conditions are largely dictated by the species of mushroom being cultivated but generally include a suitable substrate, controlled environmental parameters, and a sterile or near-sterile growing space.The core needs can be categorized as follows:

- Substrate: This is the nutrient-rich material upon which the mushroom mycelium will grow. It can range from sawdust and straw for wood-loving species to compost and manure for others.

- Environmental Control: This encompasses maintaining precise temperature, humidity, and light levels appropriate for the mushroom species.

- Sterility/Cleanliness: Preventing contamination by bacteria, molds, and other fungi is paramount. This often involves sterilization or pasteurization of substrates and meticulous hygiene practices.

- Fresh Air Exchange (FAE): Mushrooms respire and require a constant supply of fresh air to prevent the buildup of CO2, which can inhibit fruiting.

Primary Categories of Mushroom Cultivation Supplies

To meet these fundamental requirements, a range of supplies is necessary. These can be broadly grouped into categories that address substrate preparation, environmental control, and inoculation.The essential categories of supplies for a mushroom cultivation setup include:

- Substrate Materials: These are the base nutrients for mushroom growth.

- Sterilization/Pasteurization Equipment: Tools to prepare the substrate for inoculation.

- Inoculation Tools: Items used to introduce mushroom spawn to the substrate.

- Incubation and Fruiting Chambers: Controlled environments for mycelial growth and mushroom development.

- Monitoring Tools: Devices to track environmental conditions.

The Importance of Sterile Environments in Mushroom Growing

The principle of sterility, or at least a high degree of cleanliness, is arguably the most critical factor in mushroom cultivation, especially for beginners. Mushroom mycelium is a delicate organism, and its growth can be easily outcompeted by faster-growing molds and bacteria present in the air, on surfaces, and within the substrate.

“Contamination is the primary reason for cultivation failure. A sterile environment is your best defense.”

Introducing mushroom spawn into a contaminated substrate is akin to planting a seed in soil already overrun with weeds; the desired plant has little chance of survival. Therefore, employing sterilization or pasteurization techniques for substrates and maintaining rigorous hygiene throughout the process are non-negotiable steps. This prevents unwanted organisms from consuming the nutrients intended for the mushroom mycelium, thereby ensuring a healthy and productive grow.

Essential Tools for Preparing Substrates

The preparation of the substrate is a crucial step that directly impacts the success of your mushroom cultivation. This stage involves ensuring the substrate is nutritious, hydrated, and free from competing microorganisms. Various tools are indispensable for achieving these goals, ranging from simple measuring implements to more complex sterilization equipment.The following list details essential tools for preparing mushroom substrates:

- Measuring Cups and Spoons: For accurately measuring substrate ingredients and amendments. Precision in ratios is often key to substrate success.

- Large Mixing Bowls or Buckets: Sturdy containers for thoroughly combining substrate components and water.

- Pressure Cooker or Autoclave: For sterilizing substrates at high temperatures and pressures, effectively eliminating all microorganisms. This is the gold standard for sterility.

- Large Pots or Stockpots: For pasteurizing substrates using methods like the “hot water bath” technique, which reduces the microbial load without necessarily sterilizing completely.

- Thermometer: Essential for monitoring water temperatures during pasteurization and ensuring the correct temperature is maintained.

- Colander or Strainer: Useful for draining excess water after pasteurization or for sifting dry ingredients.

- Scales: For accurately weighing substrate components, especially when precise ratios are required for specific mushroom species.

- pH Meter (Optional but Recommended): Some cultivators use a pH meter to ensure the substrate falls within the optimal pH range for their chosen mushroom species.

Substrate Preparation: The Foundation of Growth

The substrate is the nutrient-rich medium that mushrooms will colonize and draw sustenance from to develop into mature fruiting bodies. Its preparation is a critical step, directly impacting the success and yield of your cultivation efforts. A well-prepared substrate provides the ideal environment for mycelial growth while minimizing the risk of contamination.Understanding the composition and preparation methods of your substrate is paramount.

This section will guide you through common materials, essential preparation techniques, and a detailed procedure for creating a grain spawn substrate, laying the groundwork for robust mycelial networks.

Common Substrate Materials

The choice of substrate material depends on the specific mushroom species being cultivated and the desired cultivation method. Each material offers a unique nutritional profile and texture that influences colonization speed and fruiting characteristics.Commonly used substrate materials include:

- Hardwood Sawdust: A widely popular choice for many wood-loving mushroom species like oyster mushrooms and shiitake. It provides good aeration and a balanced nutrient content.

- Straw: Often used for oyster mushrooms, straw is an economical and readily available option. It requires proper processing to break down its complex carbohydrates and make them accessible to the mycelium.

- Coco Coir: A byproduct of the coconut industry, coco coir is known for its excellent water-holding capacity and resistance to contamination. It is frequently mixed with other materials like vermiculite and gypsum to create a balanced substrate.

- Grain: Grains such as rye, wheat, millet, and sorghum are primarily used as spawn – the starter culture for mushroom cultivation. They are highly nutritious and colonize quickly, serving as a potent source to inoculate bulk substrates.

- Manure: Composted manure, particularly from herbivores like cows and horses, is rich in nutrients and beneficial microorganisms. It is often used for species that thrive on dung, but requires careful composting to avoid pathogens and unwanted competitors.

- Wood Chips: Larger wood chips can be used for outdoor cultivation of certain species, mimicking their natural habitat. They decompose slowly, providing a long-term food source.

Substrate Hydration and Sterilization Methods

Proper hydration ensures that the substrate contains the optimal moisture level for mycelial growth, typically between 50% and 70%. Sterilization or pasteurization is crucial to eliminate competing microorganisms that can infest the substrate and destroy the mushroom culture.The methods for achieving these conditions vary in complexity and effectiveness:

- Hydration: This is typically achieved by soaking the chosen substrate material in water for a specified period. The duration and amount of water depend on the material’s absorbency. For example, sawdust might require a shorter soak than straw.

- Pasteurization: This process uses heat to reduce the number of competing microorganisms to a manageable level, allowing the mushroom mycelium to outcompete them. Common pasteurization methods include:

- Hot Water Bath: Substrates are submerged in hot water (typically 160-180°F or 71-82°C) for a set duration, usually 1-2 hours.

- Lime Bath: Substrates are soaked in a solution of hydrated lime and water. The high pH created by the lime inhibits the growth of many contaminants.

- Sterilization: This method aims to eliminate all living organisms, including spores, bacteria, and fungi, from the substrate. This is typically achieved through high-pressure steam.

Pros and Cons of Sterilization Techniques

The choice between pressure cooking (sterilization) and pasteurization depends on the mushroom species, the substrate type, and the cultivator’s resources. Each method has its advantages and disadvantages.

Pressure Cooking (Sterilization)

Pressure cooking, most commonly done using a pressure cooker or an autoclave, subjects the substrate to steam at temperatures above boiling point (typically 15 PSI, which reaches 250°F or 121°C).

- Pros:

- Highly effective at eliminating all contaminants, offering a very clean slate for mycelial growth.

- Ideal for delicate species or substrates that are prone to contamination.

- Significantly reduces the risk of post-incubation contamination.

- Cons:

- Requires specialized equipment (pressure cooker/autoclave), which can be an initial investment.

- Can be time-consuming, with sterilization cycles often lasting 90 minutes to several hours, plus cool-down time.

- Can sometimes lead to over-hydration or a “mushy” substrate if not managed carefully, potentially hindering aeration.

Pasteurization

Pasteurization involves heating the substrate to a lower temperature for a longer duration than sterilization, targeting vegetative organisms while leaving some beneficial thermophilic bacteria.

- Pros:

- Less demanding in terms of equipment; a large pot and a heat source can suffice for some methods.

- Can be more forgiving with substrate moisture levels, as it’s less likely to overcook the material.

- Can leave behind beneficial microorganisms that may offer some competitive advantage against contaminants.

- Often quicker than full sterilization cycles.

- Cons:

- Less effective than sterilization, leaving a higher chance of surviving contaminants.

- May not be suitable for highly sensitive mushroom species or substrates.

- Requires careful monitoring of temperature and time to be effective.

Step-by-Step Procedure for Preparing a Grain Spawn Substrate

Preparing grain spawn is a fundamental step for inoculating bulk substrates. This process ensures a healthy and vigorous start for your mushroom cultivation.

Materials Needed:

- Grain (e.g., rye, wheat, millet)

- Water

- Mason jars with lids (with filter patches or modified for gas exchange) or spawn bags

- Pressure cooker

- Measuring cups and spoons

- Strainer

- Cleaning supplies (e.g., dish soap, rubbing alcohol)

Procedure:

- Cleaning the Grain: Thoroughly rinse the chosen grain under cold running water several times until the water runs clear. This removes dust and debris.

- Soaking the Grain: Place the rinsed grain in a large container and cover it with fresh water. Allow the grain to soak for 12-24 hours. This rehydrates the grains, making them more receptive to mycelial colonization. The soaking time may vary slightly depending on the grain type.

- Draining and Rinsing: After soaking, drain the water completely and rinse the grain again. Some cultivators prefer to add a small amount of gypsum (calcium sulfate) to the soaking water or during the final rinse to help prevent clumping and provide essential minerals. A common ratio is 1-2% gypsum by dry weight of grain.

- Partial Drying: Spread the soaked grain on a clean towel or screen to allow it to air dry for about 30-60 minutes. The goal is for the exterior of the grains to be dry to the touch, but the interior should remain hydrated. Avoid over-drying.

- Filling Jars or Bags: Carefully fill your mason jars or spawn bags with the prepared grain. Fill them about two-thirds to three-quarters full. This provides adequate headspace for mycelial growth and shaking. Ensure the lids are securely on the jars, with filter patches in place for gas exchange, or that spawn bags are properly sealed.

- Sterilization: Place the filled jars or bags into your pressure cooker. Add water to the pressure cooker according to the manufacturer’s instructions (usually a few inches). Seal the pressure cooker and bring it up to pressure. Sterilize the grain at 15 PSI for 90 minutes.

- Cooling: Once the sterilization cycle is complete, allow the pressure cooker to cool down naturally and completely. This can take several hours. Do not attempt to open it while it is still pressurized.

- Incubation Preparation: Once the jars or bags have cooled to room temperature, they are ready for inoculation with your mushroom culture. Store them in a clean, dark place at room temperature until you are ready to inoculate.

“The success of grain spawn lies in its ability to be easily colonized by mycelium and then effectively transfer that colonization to a larger bulk substrate. A well-prepared grain spawn is the bedrock of a productive mushroom grow.”

Sterilization and Contamination Prevention Supplies

Maintaining a sterile environment is paramount in mushroom cultivation to ensure healthy mycelial growth and prevent the proliferation of competing microorganisms. This section will detail the essential supplies and practices for achieving and maintaining the necessary level of cleanliness throughout the cultivation process.The battle against contamination begins with understanding the tools and agents that create and preserve a sterile environment.

These supplies are not merely optional; they form the bedrock of successful mushroom cultivation, safeguarding your efforts from the earliest stages of inoculation to the final harvest.

Key Equipment for Sterility

A sterile workspace and the ability to sterilize your materials are non-negotiable for preventing unwanted microbial guests. Several key pieces of equipment are instrumental in achieving and maintaining this crucial condition.

- Pressure Cooker or Autoclave: This is the most effective tool for sterilizing substrates and equipment using steam under pressure. High temperatures achieved in a pressure cooker (typically 121°C or 250°F) effectively kill bacteria, mold spores, and other contaminants.

- Laminar Flow Hood (LFH) or Still Air Box (SAB): These devices create a sterile working area to perform inoculations and transfers, minimizing the risk of airborne contaminants entering your cultures. An LFH uses a HEPA filter to provide a constant stream of filtered air, while a SAB relies on enclosed space and careful technique to achieve a similar, albeit less robust, level of protection.

- Gloves: Sterile gloves are essential for handling cultures, substrates, and spawn to prevent the transfer of microorganisms from your hands.

- Masks: Wearing a mask during inoculation and transfers helps prevent the expulsion of airborne particles from your breath, which can carry contaminants.

- Isopropyl Alcohol (IPA) Spray Bottles: 70% isopropyl alcohol is a widely used surface disinfectant for sterilizing tools, workspaces, and the exterior of containers.

- Bunsen Burner or Alcohol Lamp: These are used for flaming inoculation loops and the necks of jars or bottles during transfers to create a sterile barrier.

Sterilization Agents and Their Applications

Beyond equipment, specific chemical agents play a vital role in disinfection and sterilization. Their correct application ensures that surfaces and tools are free from microbial life.

- 70% Isopropyl Alcohol (IPA): This is the go-to disinfectant for most surfaces in a mushroom cultivation setup. It is effective against a broad spectrum of bacteria and fungi and evaporates quickly, leaving minimal residue. It is commonly used to wipe down work surfaces, tools, and the outside of containers before and during sterile procedures.

- Bleach Solutions: Diluted bleach solutions (e.g., 1:10 ratio of household bleach to water) are potent disinfectants effective against viruses, bacteria, and fungi. They are useful for disinfecting larger areas, equipment that can withstand it, and for decontaminating waste materials. However, bleach can be corrosive and its fumes can be irritating, so proper ventilation is necessary.

- Hydrogen Peroxide: Higher concentrations of hydrogen peroxide (e.g., 3%) can act as a disinfectant and mild sterilant. It breaks down into water and oxygen, making it relatively environmentally friendly. It can be used for surface disinfection and for sterilizing some equipment.

- Fumigation Agents (e.g., Potassium Permanganate and Formalin): While less common for home cultivators, these are used for large-scale sterilization of grow rooms or chambers. They are potent but require careful handling due to toxicity and are generally avoided by hobbyists.

Preventing Airborne and Surface Contamination

Contamination can enter your cultivation system through various pathways, primarily airborne particles and direct contact with contaminated surfaces. Implementing strict protocols is key to prevention.To effectively prevent contamination, a multi-faceted approach focusing on both the environment and your actions is crucial. This involves minimizing the introduction of contaminants and actively removing any that may be present.

- Work in a Clean Environment: Designate a specific area for cultivation that is as clean as possible. Minimize foot traffic and other disturbances in this area.

- Proper Air Filtration: If using a dedicated grow room, consider using HEPA filters to clean the incoming air. Ensure exhaust vents are also filtered if necessary to prevent spores from escaping and contaminating other areas.

- Regular Surface Disinfection: Frequently clean and disinfect all work surfaces, shelves, and equipment with 70% isopropyl alcohol or a suitable disinfectant.

- Minimize Air Movement During Inoculation: When performing inoculations, work within a still air box or laminar flow hood. Avoid drafts from fans or open windows.

- Sterilize All Tools and Equipment: Ensure all tools, such as scalpels, tweezers, and inoculation loops, are properly sterilized before each use, typically by flaming or soaking in alcohol.

- Properly Seal Containers: Ensure all cultivation containers, such as jars and bags, are sealed effectively to prevent the ingress of contaminants. This is where filter patches and specialized lids come into play.

- Practice Good Personal Hygiene: Always wash your hands thoroughly before starting any cultivation tasks and wear clean clothing.

Types of Filters for Mushroom Cultivation Containers

Filters are critical components in mushroom cultivation containers, allowing for gas exchange while preventing the entry of contaminants. The type of filter used can significantly impact the success of your cultivation.The choice of filter depends on the container type and the stage of cultivation, but their primary function remains the same: to facilitate the necessary exchange of gases (oxygen in, carbon dioxide out) while acting as a barrier against microscopic invaders.

| Filter Type | Description | Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Micropore Tape | A breathable tape with small pores, often used to cover holes in lids. | Early stages of colonization, simple setups. | Inexpensive, readily available. | Less reliable barrier against fine contaminants, can become clogged. |

| Poly-fill (Polyester Fiberfill) | Loosely packed synthetic fiber that allows for air exchange. | Commonly used in jars and bags, offering a simple filtration method. | Easy to use, provides moderate filtration. | Can be inconsistent in pore size, may allow some fine contaminants through. |

| Tyvek | A non-woven synthetic material with a microporous structure. | Used in filter patches for jars and bags, providing excellent filtration. | Excellent contaminant barrier, durable, allows good gas exchange. | Requires specific application methods (e.g., gluing to lids). |

| PTFE (Polytetrafluoroethylene) Filter Discs | Membrane filters with very small, uniform pores (typically 0.2 or 0.5 microns). | High-tech applications, laboratory settings, commercial cultivation, syringe filters. | Superior contaminant barrier, highly reliable, consistent performance. | More expensive, requires specialized equipment for application (e.g., heat sealing). |

Inoculation and Mycelium Development Tools

Once your substrate is prepared and sterilized, the next critical step is introducing your chosen mushroom culture. This process, known as inoculation, requires specific tools to ensure a clean and efficient transfer, setting the stage for robust mycelial growth. Developing healthy mycelium is paramount to a successful mushroom harvest, and the right equipment plays a vital role in this early stage.

Tools for Introducing Spores or Mycelium to Substrate

The successful introduction of spores or mycelium to a prepared substrate hinges on maintaining a sterile environment and utilizing precise tools. These instruments are designed to minimize contamination and facilitate the even distribution of your culture.

- Scalpel or Blade: Essential for sterile transfers of agar wedges or colonized grain. It allows for precise cutting and manipulation of fungal tissue.

- Forceps or Tweezers: Used for handling agar cultures, grain spawn, or liquid cultures without direct contact, thereby reducing the risk of contamination.

- Syringe with Needle: Primarily used for inoculating liquid cultures or for injecting liquid culture or spore syringes into bulk substrates.

- Alcohol Lamp or Torch: Crucial for flaming tools like scalpels and needles to sterilize them between uses, preventing the spread of airborne contaminants.

- Gloves and Face Mask: Personal protective equipment is vital to prevent the introduction of microbes from the user into the sterile environment.

- Still Air Box (SAB) or Laminar Flow Hood: These provide a localized sterile workspace to perform inoculations, significantly reducing the chance of airborne contaminants affecting your cultures.

Transferring Mycelium from One Culture to Another

The process of transferring mycelium, often referred to as “grafting” or “re-culturing,” is a fundamental technique in mushroom cultivation. It allows for the expansion of a healthy culture, the selection of vigorous mycelial strains, and the preparation of spawn for larger cultivation projects. This requires meticulous attention to sterility to avoid introducing competing microorganisms.

Methods for Mycelium Transfer

There are several common methods for transferring mycelium, each suited to different scenarios and culture types.

- Agar-to-Agar Transfer: This involves taking a small piece of actively growing mycelium from an existing agar plate and transferring it to a new, sterile agar plate. A sterile scalpel is used to cut a small wedge of colonized agar, which is then placed onto the fresh agar.

- Grain-to-Grain Transfer: Used to expand grain spawn. A sterile scooping tool or gloved hand is used to transfer colonized grain from one bag or jar to a new, sterilized grain substrate. This is typically done within a SAB or flow hood.

- Agar/Grain to Bulk Substrate: This is the final inoculation step before fruiting. A colonized agar wedge or a quantity of colonized grain spawn is introduced into the prepared bulk substrate.

Selecting Appropriate Inoculation Methods for Different Mushroom Species

The choice of inoculation method is influenced by the mushroom species’ growth characteristics and the cultivator’s experience level. Some species are more aggressive growers and forgiving of minor errors, while others require more delicate handling and specific techniques.

- Aggressive Species (e.g., Oyster Mushrooms): These species often grow rapidly and can outcompete minor contaminants. Grain spawn inoculation into bulk substrates is highly effective. Liquid culture can also be used for quick colonization.

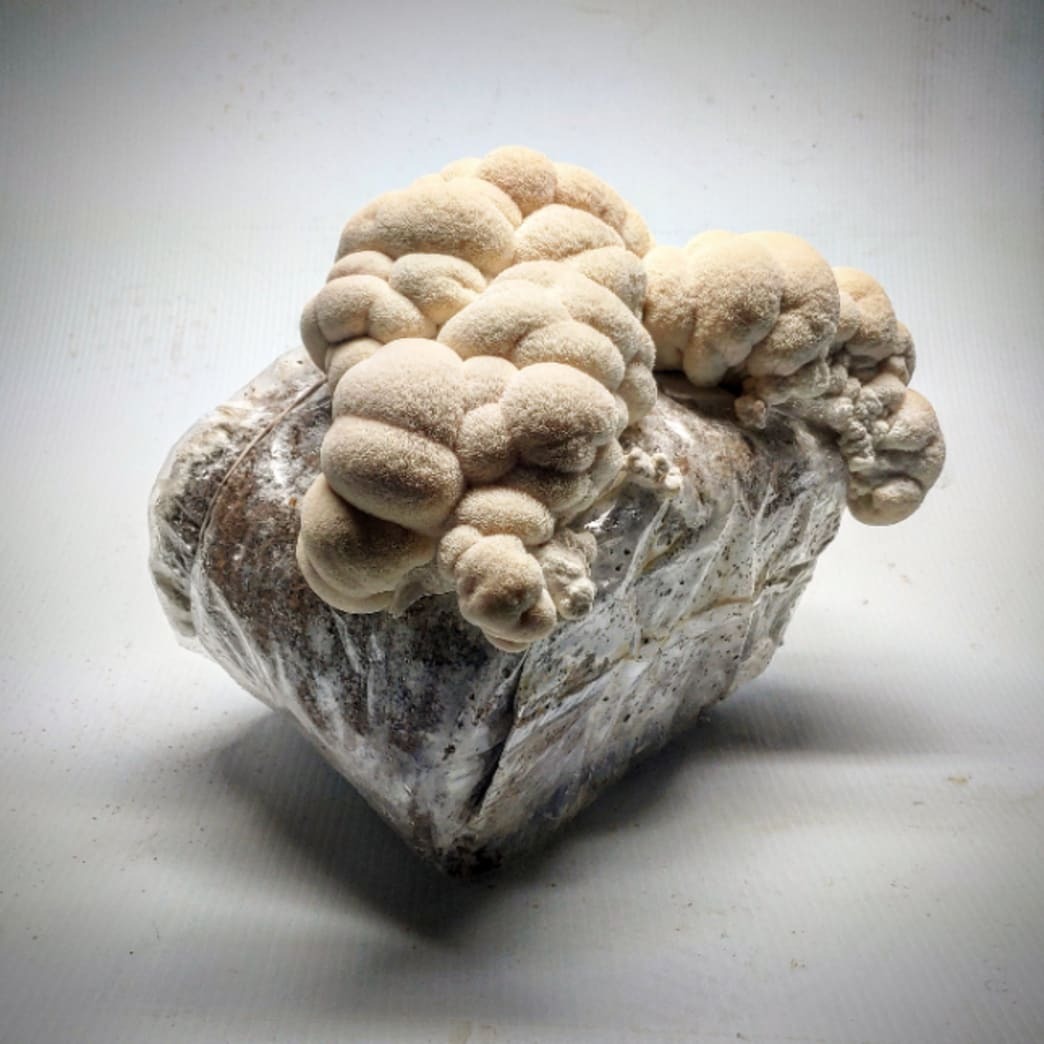

- Slower Growing or More Sensitive Species (e.g., Shiitake, Lion’s Mane): These may benefit from agar transfers to ensure a clean, vigorous start before moving to grain spawn. Meticulous sterilization is paramount.

- Spore Inoculation: For beginners or when starting from scratch, spore syringes are a common method. However, spores can be slow to germinate and may introduce genetic diversity that is not always desirable for consistent results. Agar isolation is often preferred for selecting specific genetic lines.

- Liquid Culture: Versatile for many species, liquid culture allows for easy injection into substrates and offers a good way to observe mycelial growth before inoculation.

Items for Creating Liquid Cultures

Liquid culture is a nutrient-rich liquid medium where mushroom mycelium can grow and multiply. It is an excellent tool for propagating cultures, making transfers, and inoculating substrates efficiently. Creating and maintaining liquid cultures requires a sterile setup and specific ingredients.

Essential Components for Liquid Culture Preparation

The following items are necessary for preparing and utilizing liquid cultures effectively.

- Sterile Water: Distilled or deionized water that has been sterilized, typically by autoclaving or pressure cooking.

- Nutrient Source: Common nutrient sources include honey, malt extract, or corn syrup. The sugar provides the necessary energy for mycelial growth.

- Glass Jars or Bottles: Small, heat-resistant glass jars or bottles with lids that can be sealed or modified for sterile air exchange.

- Syringes: Sterile, disposable syringes (e.g., 10cc or 20cc) are used to draw up and inject liquid culture.

- Needles: Sterile, sharp needles that fit the syringes. These are often flame-sterilized before each use.

- Micropore Tape or Filter Disks: Used to cover injection ports or air exchange holes in the lids to allow for gas exchange while preventing contamination.

- Pressure Cooker or Autoclave: Essential for sterilizing the liquid culture medium and any reusable equipment.

- Gloves and Face Mask: As with all sterile procedures, personal protective equipment is crucial.

- Still Air Box (SAB) or Laminar Flow Hood: Recommended for the inoculation of the sterile liquid medium with your mushroom culture to maintain aseptic conditions.

Fruiting Environment Setup and Control

Once your mycelium has successfully colonized the substrate, the next critical phase is to create the ideal environment for fruiting. This stage involves mimicking the natural conditions that trigger mushrooms to develop their fruiting bodies. Careful control of environmental factors is paramount to achieving a successful harvest.Mushroom fruiting is a complex biological process influenced by a delicate balance of temperature, humidity, light, and fresh air exchange.

Each of these elements plays a specific role in signaling the mycelium to transition from vegetative growth to reproductive development. Understanding and controlling these variables is key to encouraging robust and healthy mushroom growth.

Environmental Factors Crucial for Mushroom Fruiting

The transition from mycelial colonization to mushroom formation is initiated by specific environmental cues. These cues vary slightly depending on the mushroom species, but generally involve changes in temperature, increased humidity, a reduction in carbon dioxide levels, and often the introduction of light.

- Temperature: Mushrooms typically have a specific temperature range for fruiting, which is often cooler than their colonization temperature. Maintaining this optimal temperature range is vital for initiating pinning (the formation of primordia, or baby mushrooms) and for subsequent fruit body development.

- Humidity: High humidity is essential for mushroom fruiting, as the developing mushrooms are primarily composed of water. Without adequate moisture, the fruits will dry out and fail to develop properly. Relative humidity levels often need to be maintained between 80% and 95%.

- Fresh Air Exchange (FAE): As mycelium grows, it consumes oxygen and releases carbon dioxide. During the fruiting stage, mushrooms require a constant supply of fresh air to replenish oxygen and remove excess carbon dioxide. Insufficient FAE can lead to stunted growth, deformities, and increased susceptibility to contamination.

- Light: While not all mushrooms require direct sunlight, many species benefit from indirect light or a specific light cycle to orient their growth and signal the fruiting process. The intensity and duration of light can influence the shape and size of the mushrooms.

Supplies for a Controlled Fruiting Chamber

Creating a stable and controlled environment for fruiting requires specific supplies to manage the key environmental factors. These items help maintain the desired conditions, protect the developing mushrooms, and facilitate easy monitoring.A well-equipped fruiting chamber acts as a miniature ecosystem, providing the necessary conditions for your mushrooms to thrive. The following supplies are instrumental in setting up such an environment:

- Enclosure: This can be a clear plastic tote, a modified terrarium, a grow tent, or a specialized fruiting chamber. The enclosure should be large enough to accommodate your substrate blocks and allow for adequate air circulation. Transparency is beneficial for observing growth.

- Humidity Control:

- Misting bottles: For manual misting of the chamber walls and substrate surface.

- Humidifier: An ultrasonic or cool-mist humidifier can automate humidity maintenance, especially for larger setups.

- Perlite: A layer of moist perlite at the bottom of the enclosure helps to create a humid microclimate through evaporation.

- Hygrometer: An essential tool for accurately measuring and monitoring the relative humidity inside the chamber.

- Air Exchange Management:

- Ventilation holes: Strategically placed holes in the enclosure, often covered with micropore tape or filter patches, allow for passive air exchange.

- Small fan: For actively circulating air and ensuring fresh air exchange, especially in larger or sealed chambers. Timer-controlled fans can be used for automated FAE.

- CO2 monitor: For advanced control, a CO2 monitor can help ensure carbon dioxide levels are kept within the optimal range.

- Temperature Control:

- Thermometer: To monitor the temperature within the chamber.

- Heating/Cooling mats or space heaters/fans: Depending on your ambient room temperature and the specific needs of your mushroom species, these may be required to maintain the desired temperature range.

- Lighting:

- LED grow lights: Low-wattage, full-spectrum LED lights are ideal for providing the necessary light without generating excessive heat.

- Timer: To control the light cycle if an automated system is desired.

- Substrate support: Shelving or racks within the chamber to elevate substrate blocks and promote better air circulation around them.

Managing Humidity and Air Exchange in a Grow Space

Effective management of humidity and fresh air exchange is crucial for successful mushroom fruiting. These two factors are often interconnected, and their balance directly impacts mushroom development and the prevention of contamination.Maintaining the right balance between high humidity and adequate fresh air is a cornerstone of mushroom cultivation. Too little air exchange leads to CO2 buildup, while too little humidity can dry out developing mushrooms.

- Humidity Management:

- Regular Misting: Daily misting of the fruiting chamber walls and substrate surface is often necessary, especially in drier climates or with passive ventilation. Aim to mist when you observe condensation decreasing or the substrate surface appearing dry.

- Perlite Layer: A well-hydrated layer of perlite at the bottom of a tote-style chamber will continuously release moisture, contributing to ambient humidity. Rehydrate the perlite as it dries out.

- Automated Humidifiers: For larger setups or to ensure consistent humidity, ultrasonic humidifiers connected to a hygrometer-controlled outlet can maintain precise humidity levels.

- Observation: Constantly observe the chamber for condensation patterns. Light condensation on the walls is good, but heavy dripping can lead to waterlogged substrates.

- Air Exchange Management:

- Manual Fanning: For simple setups, manually fanning fresh air into the chamber several times a day can be sufficient.

- Passive Ventilation: Holes in the enclosure allow for natural air movement. The size and number of holes, along with the use of filter material, will dictate the rate of air exchange.

- Active Ventilation: Small computer fans or inline fans can be used to actively pull fresh air into the chamber and exhaust stale air. Using a timer allows for scheduled air exchange cycles.

- Balancing Act: The goal is to achieve sufficient FAE without drying out the chamber. This often involves a combination of passive and active methods, adjusted based on humidity readings and observed mushroom growth.

DIY Fruiting Chamber Designs

Constructing a DIY fruiting chamber can be an economical and rewarding way to create a controlled environment for mushroom cultivation. Many effective designs utilize common household items and readily available materials.These designs offer practical solutions for hobbyist cultivators looking to establish a dedicated fruiting space without significant investment.

- The Shotgun Fruiting Chamber (SGFC):

- Description: This popular design involves a clear plastic tote with numerous holes drilled on all six sides (bottom, top, and all four sides). The bottom is typically filled with a layer of moist perlite.

- Materials: Clear plastic storage tote with lid, drill, 1/4 inch drill bit, perlite.

- Functionality: The numerous holes allow for excellent passive air exchange, while the perlite maintains high humidity through evaporation. The clear tote provides visibility for monitoring.

- The Monotub:

- Description: A variation of the SGFC, a monotub is a large plastic tote modified with filter patches over holes to control air exchange. It is often used for bulk substrate grows.

- Materials: Large plastic tote with lid, drill, hole saw or drill bit, filter patches (e.g., polyfill, micropore tape, or specialized filter discs), bulk substrate.

- Functionality: Filter patches allow for gas exchange while preventing contaminants from entering. This design offers a more contained environment and is suitable for growing multiple substrate blocks.

- Modified Terrarium:

- Description: An existing glass or plastic terrarium can be adapted by adding ventilation holes or small fans and a humidity source.

- Materials: Terrarium, drill (if modifying plastic), perlite, misting bottle, optional small fan and timer.

- Functionality: Terrariums often have a lid that can be propped open for air exchange, and their glass construction allows for excellent visibility.

- Modified Greenhouse/Tent:

- Description: Small portable greenhouses or grow tents can be modified with additional ventilation, humidification, and lighting systems.

- Materials: Greenhouse or grow tent, fans, humidifier, timers, shelving.

- Functionality: These offer larger growing volumes and can be more easily controlled with automated systems, making them suitable for more ambitious cultivators.

The success of mushroom fruiting hinges on creating an environment that respects the mushroom’s natural life cycle, providing the precise conditions for its reproductive phase.

Harvesting and Post-Harvest Supplies

The culmination of your mushroom cultivation efforts is the harvest. Having the right tools and understanding proper techniques ensures you maximize your yield and maintain the quality of your mushrooms. This stage is as critical as the initial setup, requiring precision and care.Following a successful harvest, the subsequent steps of drying and storing are vital for preserving your bounty. Proper post-harvest handling prevents spoilage, maintains flavor, and allows for long-term enjoyment of your cultivated mushrooms.

Additionally, maintaining a clean cultivation environment after harvesting is essential for preventing future contamination and preparing for subsequent grows.

Tools for Clean Mushroom Harvesting

A clean and precise harvest is paramount to avoid damaging the delicate mushroom structures and to minimize the introduction of contaminants. The tools you select should facilitate this careful process, ensuring the integrity of both the harvested mushrooms and the substrate for future flushes.

- Sharp Knife or Scalpel: A clean, sharp blade is essential for cleanly cutting the mushroom stem at its base. This minimizes damage to the substrate and encourages subsequent flushes. Ensure the blade is sterilized before each use.

- Scissors: Small, sharp scissors can also be effective for trimming stems, especially for certain mushroom species where a clean cut is preferred over twisting.

- Tweezers: Useful for carefully plucking smaller mushrooms or removing any stray substrate particles that may cling to the harvested specimens.

- Harvesting Baskets or Trays: Clean, food-grade containers are necessary to collect your harvested mushrooms. Avoid using plastic bags directly, as this can trap moisture and promote spoilage.

Proper Handling to Avoid Damage

Mushrooms are delicate and can bruise easily, affecting their appearance and shelf life. Gentle handling throughout the harvesting and collection process is key to preserving their quality.

“Treat each mushroom with the same care you would a ripe fruit; gentle handling preserves its integrity and value.”

When harvesting, avoid squeezing or crushing the mushrooms. If a mushroom is difficult to detach, it’s often better to use a knife to cut it cleanly at the base rather than yanking, which can disturb the mycelium. For species that are harvested by twisting, a gentle rotation is sufficient. Once harvested, place them carefully into your collection containers, ensuring they are not piled too high, which can lead to crushing.

Supplies for Drying and Storing Harvested Mushrooms

Drying is a crucial step for long-term storage, as it removes moisture that can lead to spoilage and the growth of undesirable microorganisms. Properly dried mushrooms can retain their potency and flavor for extended periods.

- Food Dehydrator: This is the most efficient and reliable method for drying mushrooms. Look for one with adjustable temperature settings, as different mushroom species may benefit from slightly different drying temperatures. Aim for temperatures between 105-125°F (40-52°C).

- Drying Racks or Screens: If using a dehydrator, these are usually included. If air-drying, clean screens or racks that allow for good air circulation are essential.

- Airtight Containers: Once dried, mushrooms must be stored in airtight containers to prevent reabsorption of moisture from the air. Glass jars with tight-fitting lids or vacuum-sealed bags are ideal.

- Desiccants (Optional): Small packets of food-grade desiccant can be placed inside storage containers to further absorb any residual moisture.

- Labels and Markers: Essential for noting the mushroom species, harvest date, and drying date for easy identification and tracking.

The goal of drying is to achieve a brittle texture, where the mushrooms snap rather than bend. This typically takes several hours to a day or more, depending on the mushroom’s size, density, and the dehydrator’s efficiency.

Methods for Cleaning and Sanitizing Cultivation Equipment

After each cultivation cycle, thorough cleaning and sanitization of all equipment are non-negotiable. This practice is fundamental to preventing the spread of contaminants, such as bacteria and mold spores, which can compromise future grows.

- Cleaning Solutions: A mild dish soap and water solution is effective for removing physical debris. For sanitization, a solution of 70% isopropyl alcohol or a diluted bleach solution (1 part bleach to 9 parts water) is recommended. Always rinse thoroughly after using bleach.

- Scrub Brushes and Sponges: Various sizes of brushes are useful for scrubbing tanks, trays, and other containers. Ensure these are dedicated solely to cultivation equipment.

- Microfiber Cloths: For wiping down surfaces and equipment.

- Autoclave or Pressure Cooker (for reusable items): For sterilizing tools and containers that can withstand high heat and pressure. This is the most effective method for ensuring complete sterilization.

- Gloves: Disposable nitrile or latex gloves should be worn during cleaning and sanitization to prevent introducing contaminants from your hands.

All surfaces, containers, and tools that came into contact with the mushrooms or substrate should be cleaned immediately after use. A two-step process of cleaning (removing visible dirt) followed by sanitizing (killing microorganisms) is the most effective approach. For items that cannot be easily washed, such as filter patches on bags, a thorough wipe-down with isopropyl alcohol is a good practice.

Specialized Equipment for Advanced Cultivation

As your mushroom cultivation journey progresses, you may find that certain specialized equipment can significantly enhance both the efficiency and the overall yield of your harvests. These tools are designed to provide greater control over the cultivation environment and to ensure the highest levels of sterility, which are crucial for maximizing success, especially when working with delicate or high-value mushroom species.

Investing in these items can transform your hobby into a more professional and productive endeavor.Moving beyond the basic setup, advanced cultivators often employ equipment that automates processes, minimizes contamination risks, and allows for precise environmental management. This section will explore some of these key pieces of equipment and their benefits.

Automated Environmental Control Systems

Automated environmental control systems are a cornerstone of advanced mushroom cultivation, offering unparalleled precision and consistency in managing the critical parameters for mycelial growth and fruiting. These systems typically integrate sensors and controllers to monitor and adjust temperature, humidity, CO2 levels, and fresh air exchange, all of which are vital for optimal mushroom development. By maintaining these conditions within tight tolerances, cultivators can prevent common issues like stunted growth, mold contamination, or premature pinning.The benefits of using these systems are manifold:

- Consistency: Automated systems ensure that environmental conditions remain stable, eliminating the fluctuations that can stress cultures and reduce yields.

- Efficiency: They reduce the need for constant manual monitoring and adjustment, freeing up the cultivator’s time.

- Reproducibility: Precise control allows for the replication of successful growing conditions, leading to predictable and repeatable results.

- Problem Prevention: By maintaining optimal parameters, these systems proactively prevent many common cultivation problems before they arise.

Laminar Flow Hoods

Laminar flow hoods, also known as laminar flow benches, are indispensable tools for maintaining sterile conditions during inoculation and other critical transfer processes. They create a unidirectional, contaminant-free airflow that sweeps across the work surface, pushing airborne particles away from the area where sterile materials are being handled. This significantly reduces the risk of introducing unwanted microorganisms, such as bacteria and mold spores, into your mushroom cultures.The application of laminar flow hoods is primarily focused on sterile technique:

- Sterile Transfers: When transferring grain spawn to bulk substrate, or when cloning mushroom tissue, a laminar flow hood provides a sterile workspace to minimize contamination.

- Agar Work: For those who practice agar isolation and culture expansion, the hood is essential for preventing contamination of petri dishes.

- Syringe Preparation: Preparing spore or liquid cultures under a laminar flow hood ensures that the syringes themselves do not become contaminated.

The continuous curtain of filtered air ensures that any contaminants generated by the operator or the surrounding environment are immediately removed, creating a safe zone for delicate work.

Laboratory-Grade Equipment

For serious cultivators aiming for high yields and consistent quality, investing in laboratory-grade equipment can provide a significant advantage. These items are typically built to higher standards of precision, durability, and sterility than their consumer-grade counterparts, offering a more professional and reliable cultivation experience.The following are examples of laboratory-grade equipment suitable for dedicated cultivators:

- High-Quality Incubators: These provide precise temperature control, often with digital readouts and alarms, essential for consistent mycelial colonization.

- Digital Hygrometers and Thermometers: Accurate monitoring devices are crucial for understanding and controlling the microclimate within grow tents or chambers.

- pH Meters: For certain substrates or experimental techniques, precise pH control can be critical, and laboratory-grade pH meters offer the necessary accuracy.

- Autoclaves or Pressure Cookers: While a pressure cooker can be used for sterilization, laboratory-grade autoclaves offer higher temperatures and pressures for more effective sterilization of bulk substrates and media.

- Microscopes: For identifying contaminants, examining mycelial structures, or performing microscopic spore analysis, a good quality microscope is invaluable.

- Precision Scales: Accurate weighing of ingredients for substrates and nutrients is important for consistency and optimal results.

These pieces of equipment represent a commitment to the scientific aspects of mushroom cultivation, enabling a deeper understanding and greater control over the entire process.

Last Recap

In conclusion, a successful mushroom cultivation endeavor hinges on a well-equipped foundation. By meticulously gathering the essential supplies discussed, from substrate preparation materials to advanced environmental controls, you are setting the stage for robust growth and bountiful harvests. This comprehensive overview aims to equip you with the knowledge to confidently acquire the necessary tools, ensuring a rewarding and productive cultivation experience.