As How to Provide Proper Air Exchange for Fruiting takes center stage, this opening passage beckons readers into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original. Understanding the critical role of fresh air is paramount for successful fruiting, influencing everything from the quality of your harvest to the overall health of your cultivation environment.

This guide delves into the science behind air exchange, offering practical insights and actionable strategies.

This comprehensive exploration will illuminate the fundamental necessity of adequate ventilation during the fruiting stage for various organisms, detailing the detrimental effects of stagnant air and CO2 buildup. We will navigate the complexities of quantifying and measuring optimal air exchange rates, exploring practical methods and tools to ensure your environment is perfectly balanced. Furthermore, we will present diverse approaches to introducing fresh air, from simple passive systems to sophisticated active ventilation, alongside crucial considerations for filter selection and pressure dynamics.

Understanding Air Exchange in Fruiting Environments

The fruiting stage is a critical phase in the life cycle of many organisms, including mushrooms, cannabis, and microgreens. During this period, the organism transitions from vegetative growth to reproductive development, which requires a significantly different set of environmental conditions. Among the most vital of these conditions is proper air exchange, the process of introducing fresh air while removing stale air.

This exchange is not merely a matter of ventilation; it directly influences the health, quality, and yield of the developing fruiting bodies.Fresh air provides the essential elements and removes the byproducts of respiration, creating an optimal environment for the complex physiological processes that characterize fruiting. Without adequate air exchange, the environment can quickly become detrimental, leading to a cascade of negative consequences that compromise the entire fruiting cycle.

Understanding the specific needs of the organism and the mechanics of air exchange is therefore paramount for successful cultivation.

The Fundamental Role of Fresh Air in Fruiting

Fresh air is indispensable for the fruiting stage as it supplies the necessary oxygen for respiration and removes excess carbon dioxide (CO2) and other metabolic gases. For mushrooms, fresh air initiates the pinning process and supports the development of dense, healthy fruiting bodies. In cannabis cultivation, adequate fresh air is crucial for the flowering stage, promoting healthy bud development and preventing issues like mold and mildew.

For microgreens, air exchange ensures robust growth and prevents the buildup of humidity that can lead to damping off.

Negative Impacts of Insufficient Air Exchange

A lack of sufficient air exchange can severely hinder fruiting body development and degrade quality. In mushrooms, this can result in leggy, underdeveloped fruits with poor texture and reduced shelf life. For cannabis, insufficient air exchange during flowering can lead to airy, wispy buds with lower cannabinoid and terpene profiles, and an increased susceptibility to pathogens. Microgreens may exhibit stunted growth, elongated stems (etiolation), and a higher incidence of disease when ventilation is inadequate.

Physiological Processes Necessitating External Air

The primary physiological process driving the need for external air is respiration. Like most living organisms, fruiting bodies respire, consuming oxygen (O2) and releasing carbon dioxide (CO2) as a byproduct. This process is essential for energy production, which fuels growth and development. Furthermore, the organism releases moisture through transpiration, contributing to the overall humidity of the environment. Efficient air exchange ensures a continuous supply of O2 and the removal of accumulated CO2 and excess moisture.

The Detrimental Effects of CO2 Buildup

Carbon dioxide is a natural byproduct of respiration. While present in ambient air at approximately 400 parts per million (ppm), its concentration can rise rapidly in enclosed fruiting environments if fresh air is not adequately supplied. Elevated CO2 levels during the fruiting stage can have several detrimental effects:

- Inhibition of Fruiting: High CO2 concentrations can signal to the organism that conditions are not favorable for reproduction, potentially delaying or preventing the initiation of fruiting.

- Altered Morphology: In some organisms, prolonged exposure to high CO2 can lead to abnormal growth patterns, resulting in deformed or underdeveloped fruiting bodies.

- Reduced Quality: The metabolic stress induced by CO2 buildup can negatively impact the development of desirable compounds, such as cannabinoids and terpenes in cannabis, or affect the texture and flavor of mushrooms and microgreens.

- Increased Susceptibility to Disease: A stressed organism is often more vulnerable to opportunistic pathogens.

The optimal CO2 levels for fruiting vary by organism, but generally, maintaining levels close to ambient or slightly elevated (depending on the specific stage and species) is crucial. For instance, while some initial stages of mushroom fruiting may tolerate slightly higher CO2, the development of mature mushrooms generally benefits from lower concentrations. Similarly, cannabis flowering requires careful management of CO2 to maximize cannabinoid production and bud density.

Quantifying and Measuring Air Exchange Rates

Understanding the ideal air exchange rate (AER) is crucial for maintaining optimal fruiting conditions. This section delves into how to quantify and measure these rates, ensuring your fruiting environment is precisely calibrated for success. We will explore the calculation of AER, common units of measurement, and practical methods for monitoring key environmental parameters.

Calculating the Ideal Air Exchange Rate

Determining the ideal air exchange rate involves considering the volume of your fruiting chamber and the metabolic needs of the organism being cultivated. Different species and stages of growth have varying requirements for fresh air intake and CO2 expulsion. A general guideline can be established by considering the oxygen consumption and CO2 production rates of the organism. For many fungal fruiting bodies, a common starting point for AER is to ensure sufficient oxygen is available for respiration and to prevent excessive CO2 buildup, which can lead to malformations or stalled growth.

The ideal air exchange rate (AER) is a dynamic value influenced by fruiting chamber volume, organism type, and its metabolic activity.

A common method for estimating the AER involves understanding the organism’s metabolic load. For instance, in mushroom cultivation, the rate of CO2 production is a key indicator. A simple formula to estimate the required air changes per hour (ACH) can be derived from the CO2 production rate and the acceptable CO2 concentration limit. While precise biological data might vary, general estimations can be made based on established practices for specific species.

For example, if a specific mushroom species is known to produce a certain volume of CO2 per unit of biomass, and you have a target CO2 level (e.g., below 1500 ppm), you can calculate the airflow needed to maintain that level within your chamber volume.

Units of Air Exchange Rate

The most common unit for expressing air exchange rates is Air Changes per Hour (ACH). This metric quantifies how many times the entire volume of air within a space is replaced with fresh air in one hour. For example, an AER of 1 ACH means that the total volume of air in the fruiting chamber is replaced once every hour.

Higher ACH values indicate more frequent air exchange.

- Air Changes per Hour (ACH): This is the standard metric. An AER of 1 ACH signifies that the entire volume of air in the fruiting chamber is exchanged with fresh air every 60 minutes.

- CFM (Cubic Feet per Minute): While not a direct AER unit, CFM is often used to specify the airflow capacity of fans or ventilation systems. This can be converted to ACH by considering the chamber volume. For example, a fan providing 10 CFM in a 100 cubic foot chamber would result in 0.1 ACH (10 CFM

– 60 minutes/hour / 100 cubic feet = 6 ACH). - L/s (Liters per second): Another unit for airflow, commonly used in metric systems. Similar to CFM, it requires calculation to determine ACH based on chamber volume.

Monitoring CO2 Levels

Monitoring carbon dioxide (CO2) levels is a direct way to assess the effectiveness of your air exchange system. Elevated CO2 levels are a primary indicator that the rate of respiration from the fruiting organisms is exceeding the rate of fresh air intake. Simple and affordable CO2 meters are readily available and can provide real-time readings. These devices typically use non-dispersive infrared (NDIR) sensors to accurately measure CO2 concentrations.To use a CO2 meter:

- Place the CO2 meter in the fruiting chamber, ideally at a representative location away from direct airflow from intake or exhaust vents.

- Allow the meter to calibrate and stabilize according to its manufacturer’s instructions. This may take several minutes to an hour for some devices.

- Observe the CO2 readings over time. If the levels consistently rise above your target threshold (e.g., 1500 ppm for many fungi), it indicates that your air exchange rate is insufficient.

- Adjust your ventilation system (e.g., increase fan speed, increase fan run time, or open vents further) and monitor the CO2 levels again to see the effect.

By correlating CO2 levels with your ventilation settings, you can fine-tune your air exchange to maintain optimal conditions.

Measuring Humidity and Temperature in Relation to Air Exchange

Humidity and temperature are critical environmental parameters that are directly influenced by air exchange. While not direct measurements of AER, they serve as indicators of whether your air exchange is contributing to or detracting from the desired conditions.

Methods for Measuring Humidity and Temperature

Various tools can be used to monitor humidity and temperature within a fruiting space. The choice of tool often depends on the desired accuracy, features, and budget.

- Hygrometers and Thermometers: These are fundamental tools. Digital hygrometers and thermometers are widely available and provide relatively accurate readings. Many devices combine both functions into a single unit. Placement is key; ensure the sensor is in the fruiting zone and not directly exposed to drafts from ventilation.

- Data Loggers: For more in-depth analysis, data loggers are invaluable. They continuously record temperature and humidity over extended periods, allowing you to identify trends and correlate them with ventilation cycles. This can reveal how fluctuations in air exchange affect the microclimate.

- Integrated Environmental Controllers: More advanced systems integrate sensors for CO2, temperature, and humidity, often controlling ventilation fans and humidifiers. These systems can directly measure the impact of air exchange on these parameters and automatically adjust to maintain set points.

The relationship between air exchange and humidity/temperature is inverse: increased air exchange, especially with drier outside air, can lead to a decrease in humidity and potentially temperature. Conversely, insufficient air exchange can lead to stagnant, overly humid air. By monitoring these parameters alongside CO2, you gain a comprehensive understanding of your fruiting environment’s air dynamics. For instance, if you observe a rapid drop in humidity immediately after a ventilation cycle, it suggests that the incoming air is significantly drier than the chamber air.

This information can then inform adjustments to your humidification strategy or the frequency and duration of air exchange.

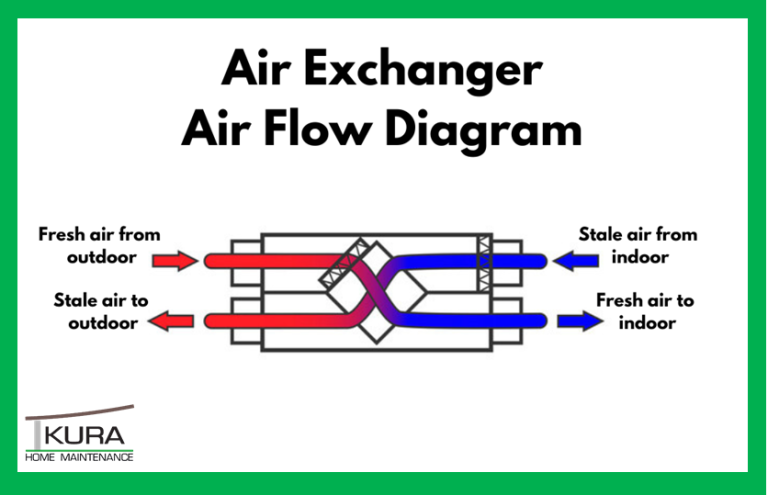

Methods for Introducing Fresh Air

Introducing fresh air into your fruiting environment is a critical step in ensuring healthy growth and optimal yields. This process directly impacts the availability of essential gases for your fruiting bodies and helps manage environmental conditions. We will explore various methods for achieving effective air exchange, from simple passive systems to more sophisticated active ventilation setups.Understanding the different approaches to air introduction will allow you to select the most appropriate method for your specific scale and needs, ensuring a consistent and beneficial supply of fresh air.

Passive Air Exchange System Design for Small-Scale Fruiting Setups

For hobbyists and small-scale cultivators, a passive air exchange system offers a simple, cost-effective, and low-maintenance solution. These systems rely on natural pressure differences and convection to facilitate air movement, minimizing the need for electrical components.The core principle of a passive system is to create strategically placed openings that allow fresh air to enter and stale air to exit. This is often achieved through variations in temperature and air density, where warmer, CO2-rich air rises and exits, drawing cooler, oxygen-rich air in from lower openings.

Material Requirements for a Passive System:

- Enclosure: A grow tent, a modified plastic tote, or a dedicated fruiting chamber. The material should be somewhat airtight but allow for the creation of controlled openings.

- Intake Vents: These are openings designed to allow fresh air to enter. For small setups, these can be as simple as drilled holes or mesh-covered slots. The size and number of intake vents will depend on the volume of your enclosure.

- Exhaust Vents: These are openings for stale air to exit. Similar to intake vents, these can be holes or slots. It is often beneficial to place exhaust vents higher than intake vents to take advantage of natural convection.

- Filter Material: A fine mesh or filter material (e.g., HEPA filter material, fine nylon mesh, or even a piece of micropore tape) is crucial for covering both intake and exhaust vents. This prevents the ingress of contaminants such as mold spores, bacteria, and insects, which can be detrimental to your fruiting bodies.

- Optional: Weather Stripping or Sealant: To ensure a relatively airtight enclosure, minor sealing around the edges of your fruiting chamber can be beneficial.

When designing, consider the total surface area of your vents relative to the volume of your fruiting chamber. A general guideline is to have a total vent area (intake + exhaust) that is roughly 5-10% of the chamber’s surface area for passive exchange, though this can vary based on environmental factors.

Active Ventilation System Components for Larger Fruiting Environments

Larger-scale fruiting operations necessitate active ventilation to maintain precise control over air exchange rates. Active systems utilize fans to force air movement, allowing for consistent and quantifiable fresh air delivery, crucial for maintaining optimal CO2 levels and preventing the buildup of detrimental gases.An active system is designed to actively draw fresh air in and expel stale air out, overcoming the limitations of natural air movement.

This ensures that the environment remains consistent, even with significant metabolic activity from large numbers of fruiting bodies. Components of an Active Ventilation System:

- Intake Fans: These fans are responsible for drawing fresh air into the fruiting environment. Inline duct fans are commonly used for their efficiency and ability to connect to ductwork.

- Exhaust Fans: These fans expel stale, CO2-rich air from the fruiting environment. Similar to intake fans, inline duct fans are a popular choice. The size and CFM (cubic feet per minute) rating of the fans should be chosen based on the volume of the fruiting space and the desired air exchange rate.

- Ducting: Flexible or rigid ducting is used to connect fans to intake and exhaust ports, allowing for precise placement of air entry and exit points within the fruiting space.

- Intake Vents and Grilles: These are the physical openings where fresh air enters the system. They are typically fitted with filters.

- Exhaust Ports: These are the openings where stale air is expelled.

- Air Filters: High-quality filters are essential for the intake air.

- Timers or Controllers: To manage the fan operation and achieve specific air exchange rates, timers or more advanced environmental controllers are used. These allow for automated cycling of the fans.

- Carbon Filters (Optional but Recommended for Odor Control): While not strictly for air exchange, carbon filters are often integrated into exhaust systems to neutralize odors generated during the fruiting process.

The placement of these components is critical. Intake fans should be positioned to draw air from a clean source, and exhaust fans should be placed to effectively remove air from the entire fruiting space.

Procedural Guide for Integrating Exhaust Fans and Intake Vents to Optimize Airflow

Optimizing airflow in a fruiting environment involves the strategic placement and integration of exhaust fans and intake vents. This ensures that fresh air is distributed effectively and stale air is efficiently removed, creating a healthy and productive atmosphere.The goal is to create a continuous and directed flow of air, preventing dead zones where CO2 can accumulate or humidity can become excessively high.

This process requires careful planning of the physical layout of your fruiting space and the placement of your ventilation components. Integration Procedure:

- Determine Air Exchange Rate: Calculate the desired air exchange rate based on the volume of your fruiting space and the metabolic activity of your fruiting bodies. For example, a common target is 1-2 air changes per hour.

- Size Fans Appropriately: Select intake and exhaust fans with sufficient CFM ratings to achieve the calculated air exchange rate. It is often advisable to have fans that can exchange the volume of your space at least once every few minutes, allowing for controlled cycling.

- Position Intake Vents: Place intake vents at a lower level within the fruiting space. If using active intake, position the intake fan to draw air from a clean, filtered source. The intake should be positioned to distribute fresh air broadly.

- Position Exhaust Vents: Place exhaust vents at a higher level, ideally on the opposite side or end of the fruiting space from the intake. This encourages a natural flow path for air. The exhaust fan should be connected to this vent.

- Connect Ducting: Use ducting to connect the exhaust fan to the exhaust vent and, if applicable, to route intake air from the fan to the intake vent. Ensure all connections are sealed to prevent air leakage.

- Install Filters: Attach appropriate filters to the intake vents and, if using a carbon filter for odor control, to the exhaust.

- Integrate Controls: Connect the fans to timers or environmental controllers. Program the controllers to cycle the fans on and off to achieve the desired air exchange rate. For instance, if you have a 100 cubic foot fruiting chamber and want 1 air change per hour, and your fan exchanges 100 CFM, you might run it for 1 minute every 60 minutes, or use a smaller fan cycled more frequently.

- Test Airflow: After installation, test the airflow. Use a smoke pen or a simple streamer to visualize the air movement and identify any stagnant areas. Adjust vent and fan placement as needed.

Proper integration ensures that the system effectively circulates air, preventing localized pockets of high CO2 or humidity.

Importance of Filter Selection for Intake Air to Prevent Contaminants

The selection of appropriate filters for intake air is paramount in maintaining a sterile and healthy fruiting environment. Fruiting bodies are highly susceptible to contamination from airborne pathogens, mold spores, bacteria, and insects, all of which can thrive in the humid conditions of a fruiting chamber.Filters act as a barrier, trapping these unwanted microscopic invaders before they can enter the fruiting space.

The effectiveness of your air exchange system is significantly diminished if the air being introduced is laden with contaminants. Key Considerations for Filter Selection:

- Micron Rating: This refers to the smallest particle size the filter can capture. For fruiting environments, a filter with a low micron rating (e.g., MERV 13 or higher, or HEPA-grade filters) is essential. HEPA (High-Efficiency Particulate Air) filters are designed to capture at least 99.97% of airborne particles 0.3 micrometers in diameter. This size is critical as many common contaminants fall within this range.

- Airflow Resistance: Filters inherently create some resistance to airflow. A filter with excessively high resistance can reduce the efficiency of your fans, leading to lower air exchange rates. It’s a balance between filtration efficiency and airflow.

- Durability and Longevity: Choose filters that are robust enough to withstand the conditions within your fruiting setup and that have a reasonable lifespan before requiring replacement.

- Type of Contaminant: While most filters target particulate matter, some applications might benefit from activated carbon filters to remove odors or volatile organic compounds (VOCs), though these are typically used on exhaust systems.

- Ease of Replacement: Filters need regular cleaning or replacement. Select filters that are easily accessible and can be swapped out without significant disruption to your fruiting process.

For example, a common issue in mushroom cultivation is contamination by Trichoderma mold, which appears as green patches. Using a high-efficiency filter on your intake will significantly reduce the chances of these spores entering your grow space in the first place, preventing costly crop losses.

Pros and Cons of Positive Pressure vs. Negative Pressure Ventilation for Fruiting

The choice between positive and negative pressure ventilation systems significantly impacts how air is managed within a fruiting environment, each offering distinct advantages and disadvantages. Understanding these differences is key to selecting the optimal system for your specific cultivation goals.Positive pressure systems aim to maintain a slightly higher pressure inside the fruiting chamber than outside, forcing air outwards. Negative pressure systems, conversely, maintain a lower pressure inside, drawing air inwards.

Positive Pressure Ventilation

Pros:

- Sterile Air Introduction: By constantly pushing air out, positive pressure helps to prevent airborne contaminants from being drawn into the chamber through any small leaks or imperfections. This can be beneficial in environments with high external contamination.

- Improved Air Circulation: The outward flow of air can help to distribute fresh air more evenly throughout the chamber, reducing dead zones.

- Reduced Odor Escape: If odors are a concern, positive pressure can help to contain them within the chamber, provided exhaust is filtered.

Cons:

- Potential for Leaks: Any leaks in the enclosure will allow air to escape, which can be inefficient and lead to uncontrolled moisture loss.

- Requires Careful Sealing: Maintaining consistent positive pressure requires a very well-sealed enclosure.

- Fan Strain: If the enclosure is not perfectly sealed, fans may have to work harder to maintain pressure.

Negative Pressure Ventilation

Pros:

- Containment of Contaminants: Air is drawn inwards, so any small leaks will pull ambient air into the chamber, rather than allowing internal air (which may contain spores or undesirable microorganisms) to escape. This is often preferred for preventing the spread of contaminants to surrounding areas.

- Moisture Retention: It can be easier to maintain humidity levels as air is being pulled in rather than pushed out.

- Simpler Sealing Requirements: While good sealing is always beneficial, negative pressure is generally more forgiving of minor imperfections than positive pressure.

Cons:

- Risk of Contaminant Ingress: If the intake air is not adequately filtered, contaminants can be easily drawn into the fruiting environment.

- Odor Escape: Odors generated within the chamber can escape through any leaks in the enclosure.

- Less Even Air Distribution: If not carefully designed, negative pressure can create uneven airflow patterns.

For many fruiting applications, especially those where preventing the escape of airborne contaminants or odors is a priority, negative pressure with a well-filtered intake is a common and effective choice. However, in environments where the external air is significantly more contaminated than the internal environment, positive pressure with filtered exhaust can be advantageous.

Optimizing Air Exchange for Specific Fruiting Organisms

Successfully cultivating various fruiting organisms requires a nuanced approach to air exchange, as each species and growth stage has distinct environmental needs. Understanding these specific requirements is crucial for maximizing yield, quality, and preventing common cultivation issues. This section delves into the tailored air exchange recommendations for several popular fruiting organisms.

The ideal air exchange rate is not a one-size-fits-all solution. Factors such as the organism’s metabolic rate, its stage of development (e.g., vegetative growth, fruiting, maturation), and the environmental conditions within the grow space (e.g., humidity, temperature, CO2 levels) all play a significant role in determining the optimal air exchange rate.

Gourmet Mushroom Fruiting Air Exchange Recommendations

Gourmet mushrooms, particularly species like oyster mushrooms (Pleurotus spp.), shiitake (Lentinula edodes), and lion’s mane (Hericium erinaceus), have specific air exchange needs during their fruiting phase. Insufficient fresh air can lead to stunted growth, deformed fruits, and increased susceptibility to contaminants. Conversely, excessive air exchange can dry out the substrate and the developing mushrooms.

Generally, the air exchange rate for gourmet mushroom fruiting is expressed in terms of Air Changes Per Hour (ACH). A common range recommended for many gourmet mushroom species during fruiting is:

- Oyster Mushrooms (Pleurotus spp.): 1 to 4 ACH. Higher rates are often beneficial during the initial pinning and rapid growth stages.

- Shiitake Mushrooms (Lentinula edodes): 0.5 to 2 ACH. Shiitake can be slightly more sensitive to over-ventilation.

- Lion’s Mane (Hericium erinaceus): 1 to 3 ACH. Similar to oyster mushrooms, good airflow is important for developing their characteristic “teeth.”

These values are guidelines, and the specific optimal rate can be influenced by the density of fruiting bodies, the size of the grow space, and the overall humidity control strategy. Monitoring CO2 levels is an excellent way to fine-tune air exchange, aiming to keep CO2 below 1000-1500 ppm during fruiting.

Cannabis Flowering Phase Air Exchange Requirements

During the flowering phase, cannabis plants undergo significant metabolic activity to develop dense, resinous buds. This process requires a steady supply of fresh oxygen and the removal of excess carbon dioxide, water vapor, and volatile organic compounds (VOCs) released by the plants. Proper air exchange is critical for preventing mold and mildew, managing temperature and humidity, and ensuring optimal cannabinoid and terpene development.

For flowering cannabis, a common recommendation for air exchange is to aim for at least one full air change per minute, which translates to approximately 60 ACH. This high rate is necessary to:

- Remove excess humidity: Transpiration from plants during flowering can significantly increase humidity, creating an ideal environment for bud rot (Botrytis cinerea).

- Replenish CO2: Plants consume CO2 during photosynthesis, and a constant supply is needed for vigorous growth and cannabinoid production.

- Control temperature: Grow lights and plant respiration generate heat, which must be effectively dissipated.

- Manage VOCs: The removal of VOCs contributes to a cleaner air environment and can impact terpene profiles.

In practice, this is often achieved using oscillating fans to ensure air movement within the canopy and exhaust fans connected to ducting, potentially with carbon filters to manage odor. The goal is to maintain a stable environment, typically with temperatures between 70-80°F (21-27°C) and relative humidity between 40-50% during flowering.

Microgreen Cultivation Air Exchange Needs

Microgreens are characterized by their rapid growth cycles, often harvested within 7 to 21 days. Their high density and rapid respiration rates during germination and early growth demand efficient air exchange to prevent issues associated with stagnant air and high humidity.

While microgreens don’t have the same CO2 depletion issues as larger plants due to their shorter growth cycles and less intense light requirements, air exchange is still vital for:

- Preventing fungal diseases: The high density of microgreens can trap moisture, making them susceptible to damping-off diseases and molds. Fresh air helps to dry surfaces and reduce humidity.

- Managing temperature: Respiration and ambient conditions can lead to temperature fluctuations that can stress young seedlings.

- Ensuring uniform growth: Consistent air movement helps to prevent hot spots and ensures that all seedlings receive adequate gas exchange.

For microgreens, a moderate air exchange rate is typically sufficient, often in the range of 1 to 3 ACH. This can be achieved through passive ventilation (e.g., opening vents) or low-speed oscillating fans that provide gentle air circulation. The key is to avoid direct, strong drafts that can damage the delicate seedlings while ensuring a constant exchange of air to maintain a healthy microclimate.

Common Challenges in Maintaining Proper Air Exchange and Solutions

Maintaining optimal air exchange for different fruiting organisms presents several common challenges. Addressing these proactively is key to successful cultivation.

Challenge: Inconsistent CO2 Levels

Description: In sealed or poorly ventilated environments, CO2 can become depleted by plants or accumulate to excessively high levels due to respiration, negatively impacting growth. For mushrooms, high CO2 during fruiting can lead to long stems and small caps. For plants, low CO2 limits photosynthesis.

Solutions:

- Install automated ventilation systems with CO2 sensors that trigger air exchange based on real-time CO2 levels.

- For smaller setups, manual ventilation schedules can be implemented, opening vents or turning on fans at regular intervals.

- In environments where CO2 enrichment is used, precise control systems are essential to maintain the target levels without overshooting.

Challenge: Humidity Imbalances

Description: Over-ventilation can lead to excessive drying of substrates or plants, while insufficient ventilation traps humidity, promoting fungal growth and disease. This is particularly problematic for mushrooms and the flowering stage of cannabis.

Solutions:

- Utilize humidifiers and dehumidifiers in conjunction with ventilation systems to maintain target humidity ranges.

- Employ fans to circulate air within the grow space, which helps to distribute moisture evenly and prevent condensation on surfaces.

- Adjust fan speed and run times based on humidity readings, rather than relying solely on fixed schedules.

Challenge: Temperature Fluctuations

Description: Inadequate air exchange can lead to heat buildup from lights and respiration, or cold spots in poorly insulated areas, stressing the organisms and affecting their development. This is critical for all fruiting organisms, as optimal temperature ranges are vital for their life cycles.

Solutions:

- Integrate exhaust fans with intake vents to create a controlled airflow that effectively removes heat.

- Use oscillating fans to ensure even temperature distribution throughout the grow space.

- Consider using inline fans with thermostats to automatically regulate temperature by controlling ventilation.

Challenge: Odor Management (Especially for Cannabis)

Description: The strong odors produced by flowering cannabis can be a significant issue, requiring effective air exchange and filtration.

Solutions:

- Employ carbon filters connected to exhaust fans. These filters effectively capture and neutralize volatile organic compounds responsible for odors.

- Ensure that exhaust air is directed away from sensitive areas or neighboring properties.

Challenge: Contamination Risk

Description: Stagnant air and high humidity create environments conducive to the growth of molds, bacteria, and pests, which can devastate a crop. This is a constant concern for mushroom cultivation and microgreens.

Solutions:

- Maintain strict hygiene protocols in the grow area.

- Use filtered intake vents to prevent the entry of airborne contaminants.

- Ensure adequate air circulation to minimize damp spots and reduce the likelihood of mold growth.

- Regularly monitor crops for early signs of contamination and take immediate corrective actions.

Controlling Environmental Factors Through Air Exchange

Proper air exchange is a cornerstone of successful fruiting, extending its influence beyond simply providing fresh air. By strategically managing the rate at which air is exchanged, cultivators can exert significant control over critical environmental parameters like temperature, humidity, and condensation, ultimately fostering optimal conditions for fungal development. This section delves into the nuanced ways air exchange impacts these factors and how to leverage this control for consistent and robust yields.

Temperature Regulation via Air Exchange

Temperature fluctuations within a fruiting chamber can significantly stress developing mycelium and inhibit proper fruiting. Adjusting air exchange rates provides a direct mechanism for managing these temperature variations. Introducing fresh, ambient air into the chamber can help dissipate excess heat generated by metabolic processes within the fruiting body or by external heat sources. Conversely, in cooler environments, reducing air exchange can help retain warmth, preventing temperatures from dropping too low.

The volume of air exchanged directly correlates with the rate of heat transfer. Higher air exchange rates lead to more rapid cooling, while lower rates promote heat retention.

Air Exchange and Humidity Management

The relationship between air exchange and humidity control is intricate and vital for preventing detrimental conditions such as excessive condensation. Fruiting organisms respire, releasing moisture into the environment, which increases humidity. Without adequate air exchange, this moisture can accumulate, leading to water droplets forming on surfaces within the fruiting chamber. This condensation can promote bacterial growth and disease, and can also lead to “raining” on developing fruits, which can be harmful.

By increasing air exchange, moist air is expelled and replaced with drier, fresh air, thereby lowering the relative humidity. Conversely, in very dry environments, a carefully controlled, lower air exchange rate can help conserve humidity.

Preventing Condensation with Air Exchange

Condensation occurs when warm, moist air comes into contact with cooler surfaces. Air exchange plays a crucial role in preventing this by continuously removing the saturated air before it has a chance to cool and condense. A consistent, moderate rate of air exchange helps maintain a stable internal temperature, reducing the likelihood of significant temperature gradients that drive condensation. If condensation is observed, increasing the air exchange rate is the primary method to address it.

This will vent the humid air and introduce drier air, helping to evaporate the existing moisture.

Automating Air Exchange with Timers and Sensors

Achieving consistent environmental conditions necessitates reliable and automated control of air exchange cycles. Timers and sensors are indispensable tools for this purpose. Timers allow for the programming of specific on/off cycles for ventilation fans, ensuring that air exchange occurs at predetermined intervals and durations. This is particularly useful for mimicking natural diurnal cycles or for implementing specific air exchange strategies throughout different growth phases.Sensors, such as hygrometers (for humidity) and thermometers (for temperature), provide real-time data on environmental conditions within the fruiting chamber.

When integrated with a controller or timer, these sensors can trigger ventilation cycles automatically when specific thresholds are met. For instance, a humidity sensor could activate the fan when the relative humidity exceeds a set point, or a temperature sensor could trigger ventilation if the internal temperature rises above the desired range. This automation ensures that the environment remains within optimal parameters without constant manual intervention, leading to more stable and predictable fruiting.

Example of Automated Control Setup

A common setup involves a digital timer connected to a small exhaust fan and an intake vent. The timer can be programmed to run the fan for 15 minutes every hour. For more advanced control, a humidity controller can be linked to the fan. In this scenario, the fan would only activate when the humidity sensor detects levels above, for example, 90%, and would continue to run until the humidity drops to 85%.

This prevents over-ventilation and conserves energy while effectively managing humidity.

Scheduling Air Exchange Rates for Fruiting Stages

Different stages of the fruiting process have distinct environmental requirements, and air exchange rates should be adjusted accordingly. A well-planned schedule ensures that the fruiting organism receives the appropriate level of fresh air and CO2 removal at each phase of its development.

Initiation Stage (Pinning/Primordia Formation)

During the initiation stage, when the mycelium is forming primordia (pins), a lower rate of air exchange is often preferred. High levels of fresh air can dry out the substrate and developing pins. The primary goal is to maintain high humidity and a relatively stable CO2 concentration.

- Humidity: Maintain relative humidity above 90%.

- CO2: Elevated CO2 levels are generally beneficial for initiating pinning.

- Air Exchange: Minimal, perhaps a few minutes of fan operation once or twice a day, or relying on passive diffusion if the chamber is not perfectly sealed.

Growth Stage (Development of Fruiting Bodies)

As the pins develop into mature fruiting bodies, the demand for fresh air increases significantly. The fruiting bodies respire more actively, producing CO2 and consuming oxygen. A higher rate of air exchange is crucial to prevent CO2 buildup and to ensure adequate oxygen supply.

- Humidity: Maintain relative humidity between 85-90%.

- CO2: Lower CO2 levels are required; aim for ambient or slightly elevated levels.

- Air Exchange: Moderate to high. This could involve running fans for 15-30 minutes every 1-2 hours, or a continuous low-level exchange.

Harvest Stage

As the fruits mature and approach harvest, the air exchange requirements may remain similar to the growth stage, or slightly adjusted based on observation. Ensuring good air circulation helps prevent the development of contaminants and promotes healthy fruit development right up to harvest.

- Humidity: Maintain relative humidity between 80-90%.

- CO2: Keep CO2 levels low.

- Air Exchange: Consistent moderate to high exchange, similar to the growth stage.

Post-Harvest / Second Flush Preparation

After harvesting, the substrate may be rehydrated. During this period, air exchange might be reduced again to help retain moisture during rehydration, before resuming a schedule suitable for initiating another flush of fruits.

“The art of fruiting lies not just in providing the basics, but in finely tuning the environment, and air exchange is your most powerful dial.”

Troubleshooting Air Exchange Issues

Effective air exchange is paramount for successful fruiting, and when it falters, recognizing and rectifying the issues promptly is crucial. This section delves into identifying the tell-tale signs of inadequate ventilation and Artikels practical approaches to diagnose and resolve common problems, ensuring optimal conditions for your fruiting organisms.

Signs of Inadequate Air Exchange

Several observable indicators can signal that your fruiting environment is not receiving sufficient fresh air. These signs often manifest as changes in the environment or the fruiting bodies themselves, pointing towards a buildup of metabolic byproducts or a lack of essential gases.

- Stagnant Air: A noticeable lack of air movement, often felt as a heavy or stuffy atmosphere within the fruiting chamber.

- Increased CO2 Levels: Fruiting organisms, particularly fungi, produce carbon dioxide during their metabolic processes. High CO2 levels can lead to deformities, stunted growth, or premature pinning. This can be visually identified by elongated stems and underdeveloped caps in many mushroom species.

- Reduced Oxygen Levels: Conversely, inadequate fresh air intake means a depletion of oxygen, which is vital for respiration and healthy development.

- Mold and Bacterial Contamination: Stagnant, humid air creates an ideal breeding ground for unwanted microorganisms. An increase in fuzzy molds or slimy bacterial colonies can be a direct consequence of poor air exchange.

- Unpleasant Odors: The accumulation of metabolic waste products can result in a musty, sour, or otherwise unpleasant smell emanating from the fruiting space.

- Poor Fruit Body Development: This can manifest in various ways depending on the organism, including small, misshapen fruits, a lack of proper differentiation between stem and cap, or a failure to initiate fruiting altogether.

Diagnosing Ventilation System Malfunctions

When issues arise, a systematic approach to diagnosing your ventilation system can pinpoint the source of the problem. This involves checking the components of your air exchange setup for proper function and integrity.

- Inspect Fans and Motors:

- Ensure fans are powered on and spinning. Listen for unusual noises that might indicate motor strain or bearing failure.

- Check for obstructions in fan blades or vents that could impede airflow.

- Verify that fans are set to the correct speed or timer settings as per your cultivation plan.

- Examine Air Filters:

- Clogged filters are a common cause of reduced airflow. Visually inspect filters for dust, debris, or microbial growth.

- If filters are dirty, replace or clean them according to the manufacturer’s recommendations. Regular filter maintenance is essential for sustained performance.

- Check Ductwork and Tubing:

- Inspect all air ducts, tubes, and connections for leaks, kinks, or blockages. Even small leaks can significantly reduce the volume of air being exchanged.

- Ensure ductwork is properly sealed to prevent air from escaping or unwanted contaminants from entering.

- Verify Environmental Control Settings:

- If using automated systems (e.g., controllers for fans, CO2, or humidity), confirm that the settings are correct and the system is responding as expected.

- Check sensor calibration if possible, as inaccurate readings can lead to incorrect ventilation adjustments.

- Assess Timer and Controller Functionality:

- For timed ventilation, ensure the timer is functioning correctly and cycling the fans on and off at the desired intervals.

- If using a more advanced controller, review its programming and diagnostic logs for any error messages or anomalies.

Resolving Stagnant Air Pockets

Stagnant air pockets, areas within the fruiting space where air does not circulate effectively, can lead to localized issues like mold growth or uneven development. Addressing these requires strategic air movement.

- Introduce Oscillating Fans: Small, low-speed oscillating fans placed strategically within the fruiting chamber can gently move air and break up stagnant zones. Avoid directing fans directly at developing fruits, which can cause drying.

- Adjust Fan Placement and Direction: Experiment with the placement and angle of your primary intake and exhaust fans. Ensure they are positioned to create a consistent airflow pattern throughout the entire space, rather than creating dead zones.

- Increase Air Exchange Rate Temporarily: During periods where stagnant air is a concern, a temporary increase in the overall air exchange rate can help to purge stale air and introduce fresh air more effectively. Monitor humidity levels closely when doing so.

- Utilize Baffles or Diffusers: In larger or more complex fruiting environments, baffles or diffusers can be used to guide and spread airflow, ensuring that fresh air reaches all corners of the chamber.

- Consider a Larger or Additional Fan: If persistent stagnant air pockets are an issue, it may indicate that the current fan capacity is insufficient for the size of the fruiting space. Upgrading to a more powerful fan or adding a secondary fan might be necessary.

Addressing Humidity Imbalances from Air Exchange

Improper air exchange can directly impact humidity levels, leading to either excessive dryness or overly damp conditions. The key is to balance the rate of air exchange with your humidity control measures.

Solutions for Excessive Dryness

When air exchange is too high or not adequately humidified, the fruiting environment can become too dry, hindering development.

- Reduce Air Exchange Rate: If your system allows for variable control, slightly decrease the frequency or intensity of air exchange. This will retain more moisture within the chamber.

- Increase Humidification Efforts: Supplement your existing humidification system. This could involve using a larger humidifier, misting more frequently, or employing ultrasonic foggers.

- Utilize Humidity-Retaining Substrates: Ensure your substrate or growing medium has adequate moisture retention capabilities.

- Cover or Seal Leaks: Check for and seal any unintended air leaks in your fruiting chamber that might be contributing to rapid moisture loss.

- Employ Humidity Domes or Lids: For smaller setups, using humidity domes or lids can help trap moisture within the immediate fruiting area, creating a more humid microclimate.

Solutions for Excessive Humidity

Conversely, inadequate air exchange can trap moisture, leading to high humidity, which can promote mold and bacterial growth and inhibit proper fruiting.

- Increase Air Exchange Rate: This is the primary solution. Increase the frequency or duration of fresh air intake to vent excess moisture.

- Improve Exhaust Ventilation: Ensure your exhaust fan is adequately sized and functioning properly to effectively remove moist air from the chamber.

- Use a Dehumidifier: In persistently humid environments, a small dehumidifier placed outside or carefully within the fruiting space (if designed for such conditions) can help regulate moisture levels.

- Introduce Gentle Air Circulation: While increasing air exchange, ensure there is also gentle internal air circulation to prevent condensation buildup on surfaces.

- Adjust Humidifier Settings: If your humidifier is set too high or running too frequently, recalibrate its settings to avoid over-saturating the air.

Summary

In conclusion, mastering air exchange is not merely a technical detail but a cornerstone of successful fruiting. By diligently applying the principles and techniques discussed, from precise measurement to strategic system design and targeted troubleshooting, you can cultivate an environment where your fruiting organisms thrive, yielding superior quality and quantity. This journey ensures your efforts are met with robust growth and exceptional results, making proper air exchange an indispensable element of your cultivation practice.